Limestone quarry crushing technology | SRK Consulting

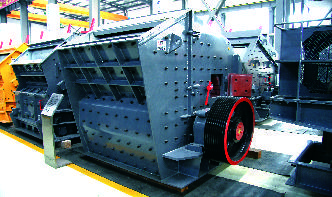

crusher reloion at limestone quarry project SRK has developed a new plan with the quarry operators that details a new crusher loion to secure future production. The quarry is a strategic source of limestone products for steel production, civil construction and agriculture to a wide European market.