Roller Mill | Mill (Grinding) | Wear

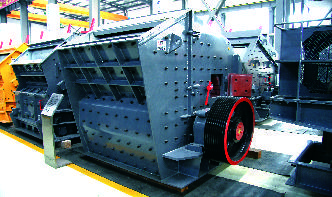

Roller Mills With FlatSurfaced Rollers Basic Arrangement of Separators for Roller Mills. Dynamic Separator DESIGN FEATURES Roller Mills with Conical Rollers Roller Mills with ConvexSurfaced Rollers The grinding elements in the roller mill should develop a good drawin action. The grinding elements should have adequate pressure.