HP cone crusher main Components

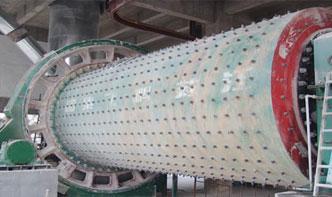

HP cone crusher main Components Languages. English German ... Large bronze bearing Cone crusher socket liner Cone crusher spider bushing Crusher shaft High Chromium parts High manganese steel Jaw crusher plate side plate Other bronze parts Other steel parts Ball mill steel ball Steel factory. HP3 cone crusher HP4 cone crusher HP5 cone crusher .