Milling

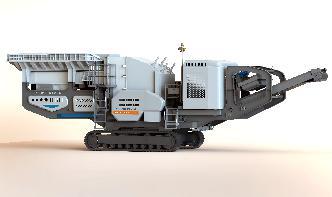

Staffs Powder Processing custom mills powders and liquids using a wide range of machinery including ball mills and crushers. We can mill anything from clays and Frits to glass and pigments using our equipment in Staffordshire, UK. Ball milling is our speciality and we operate several machines able to cope with any sized quantity.