Stirred Milling Technology – A New Concept in Fine Grinding

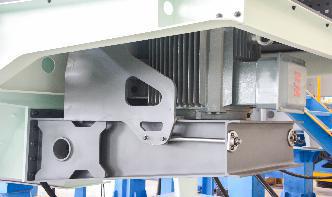

Mill structure The vertical stirred media grinding mill uses a grinding chamber filled with small beads whereby comminution takes place by attrition between the beads. The stirring effect is caused by rotating discs mounted on a shaft. There are also stationary discs on the mill body positioned in .